An often overlooked but deadly workplace hazard, arc flash can have devastating consequences, making it necessary to know all about arc flash safety. But what exactly is arc flash, and how can you protect yourself and your employees? Let’s dive in.

- What Is An Arc Flash?

- What Can Cause An Arc Flash?

- What’s The Difference Between An Arc Flash and An Arc Blast?

- The Dangers Of An Arc Flash

- How To Avoid An Arc Flash

- Arc Flash Assessment

Keep in mind that this article is not an exhaustive resource. If you work with electrical equipment and are unsure about arc flash safety, please reach out to your supervisor about receiving the proper training.

Looking for arc flash safety training? With over 200 years of combined experience, ACUTE offers more than theoretical or abstract ideas. For a full list of our courses click here.

1. What Is An Arc Flash?

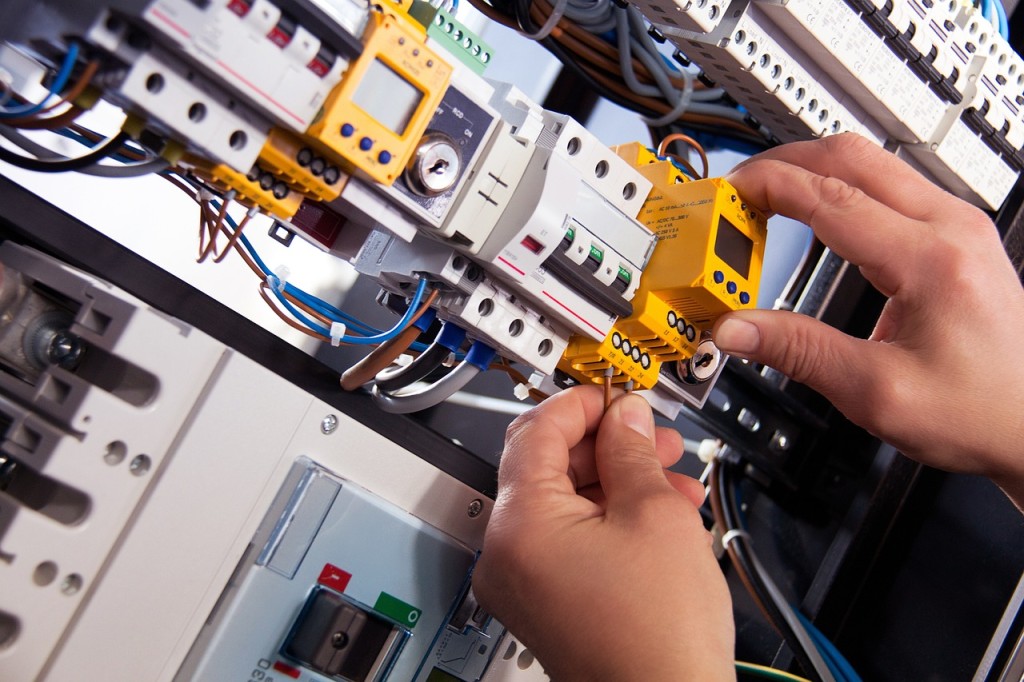

It’s crucial to be aware of what can trigger an arc flash. IMG: Pixabay.

An arc flash is a sudden, explosive release of energy that occurs when an electrical current travels through the air to the ground or another conductive body. This phenomenon can produce intense heat, light, and pressure, posing serious risks to anyone nearby, so it’s crucial to know about arc flash safety.

The key characteristics of an arc flash are:

- Extreme temperatures: Arc flash temperatures can reach up to 10,000 degrees Fahrenheit, instantly igniting clothing and causing severe burns.

- Explosive force: The pressure wave generated by an arc flash can be powerful enough to throw individuals and objects back.

- Bright light: The intense light emitted by an arc flash can cause temporary blindness and eye damage.

An arc flash is different from other electrical risks because:

- Arc flash is primarily a thermal hazard, with the intense heat and light being the primary dangers

- Electrical shock, on the other hand, involves the passage of electrical current through the body, leading to potential cardiac arrest, muscle contractions, and burns.

It’s crucial to understand that while both pose significant risks in electrical environments, the mechanisms and consequences are distinct.

2. What Can Cause An Arc Flash?

Arc flashes are often triggered by a combination of factors, including:

- Equipment failures: Worn insulation, loose connections, or damaged components can create conditions for an arc flash.

- Human error: Mistakes during electrical work, such as accidental contact with energized parts, can initiate an arc flash.

- Environmental factors: Dust, moisture, or other contaminants can contribute to the formation of an arc flash.

- Power surges or voltage fluctuations: These can stress electrical systems and increase the risk of an arc flash.

It’s important to note that even seemingly minor electrical issues can escalate into an arc flash. Regular equipment maintenance and adherence to arc flash safety protocols are crucial in preventing these hazardous events.

3. What’s The Difference Between An Arc Flash And An Arc Blast?

Arc blasts are the results of the pressure wave caused by an arc flash. IMG: Pixabay.com

An arc blast is a powerful pressure wave generated by the rapid expansion of air and vaporized metal during an arc flash.

When an electrical arc occurs, the intense heat causes surrounding materials to vaporize almost instantly. This rapid expansion creates a shockwave or blast that can be incredibly forceful.

Effects of an Arc Blast

- Physical trauma: The force of the blast can throw people to the ground and cause injuries.

- Hearing damage: The sudden, loud noise can lead to temporary or permanent hearing loss.

- Debris: The blast can propel objects with great force, causing additional injuries.

To summarize: While an arc flash is the intense light and heat produced by an electrical explosion, an arc blast is the resulting pressure wave that can cause physical harm.

4. The Dangers Of An Arc Flash

An arc flash can cause serious burn and blast injuries. IMG: Pixabay.com

Two of the worst effects of an arc flash are burns and blast injuries which can be life-threatening and could require extensive medical attention:

- Severe burns: Arc flash burns are often deep, penetrating, and cover large areas of the body. They can require multiple surgeries, skin grafts, and long-term rehabilitation.

- Long-term consequences: Burn victims may experience chronic pain, disfigurement, and psychological trauma.

- Blast injuries: In addition to the physical injuries mentioned, blast injuries can also lead to concussions, internal organ damage, and hearing loss.

An arc flash can also cause extensive structural damage:

- Extent of structural damage: Arc blasts can cause significant damage to walls, ceilings, and electrical panels, creating hazards for occupants and hindering recovery efforts.

- Equipment loss: The intense heat and pressure from an arc flash can destroy essential equipment, leading to costly replacements and business disruptions.

Finally, if the blast reaches hazardous materials, the following can occur:

- Fire hazards: Fires ignited by arc flashes can spread rapidly, especially in environments with flammable materials. This poses a significant risk to life and property.

- Environmental impact: The burning of materials can release toxic fumes and smoke, contaminating the air and posing health risks to those in the vicinity.

In summary, not only can arc flashes cause serious injuries, stuctural damage and fire hazards are also possible.

5. How To Avoid An Arc Flash

Precautionary measures should always be taken to avoid arc flash. IMG: Pixabay.

Just like other workplace precautionary measures, the key component to arc flash safety is knowing how to prevent one from happening in the first place. This includes:

- Proper electrical safety training: All workers should receive the proper training and understand how to keep a safe distance in areas where an arc flash could potentially occur.

- Personal protective equipment (PPE): Wearing specialized clothing designed to withstand arc flash is essential for those working near electrical equipment. A proper PPE outfit should include flame resistant clothing such as gloves, shirts, pants, boots and a face shield. A hard hat can alos protect the worker from falling debris.

- Proper labelling of electrical equipment: This can help workers be aware of voltages and currents, as well as any other vital information.

- Regular equipment inspection and maintenance: Ensuring electrical systems are in good condition can help prevent arc flashes.

- Arc flash risk assessment: Identifying potential arc flash hazards and implementing control measures is crucial.

Remember, arc flash hazards are serious and can lead to severe injuries or fatalities. Always prioritize safety when working with electricity.

6. Arc Flash Assessment

A thorough arc flash assessment can help prevent one from happening. Video: YouTube.

As mentioned above, an arc flash assessment will help with arc flash safety. To accurately assess the risk of an arc flash, consider the following factors:

- Electrical System Configuration: Understanding the voltage levels, power sources, and system layout is crucial.

- Equipment Condition: The age, maintenance history, and overall condition of electrical equipment significantly impact the risk of an arc flash.

- Workplace Environment: Factors like dust, moisture, and temperature can influence the likelihood of an arc flash.

- Worker Activities: The types of tasks performed near electrical equipment and the frequency of those tasks determine exposure levels.

- Historical Data: Reviewing incident reports and near-miss events can provide valuable insights into potential hazards.

Determining Arc Flash Boundary and Incident Energy

- Arc Flash Boundary: This defines the area around electrical equipment where the potential for severe burns exists in the event of an arc flash.

- Incident Energy: This measures the amount of energy released during an arc flash and is used to determine the appropriate level of PPE required.

Implementing Control Measures

Based on the assessment, appropriate control measures should be implemented, including:

- Engineering Controls: Modifications to electrical systems, such as installing arc-resistant equipment or implementing isolation procedures.

- Administrative Controls: Procedures and work practices to minimize exposure to arc flash hazards, including job safety analysis and lockout/tagout procedures.

- Personal Protective Equipment (PPE): Providing employees with appropriate arc-rated clothing, face protection, and gloves to protect against the effects of an arc flash.

- Training and Awareness: Educating employees about arc flash hazards, prevention, and response procedures is essential.

By conducting thorough arc flash risk assessments and implementing effective control measures, organizations can significantly reduce the risk of injury and fatalities.

Arc flash safety is non-negotiable. By understanding the risks, implementing preventative measures, and ensuring proper training, you can significantly reduce the likelihood of an arc flash incident occurring in your workplace. Remember, even one incident is one too many. Make safety a priority for everyone in your organization.

Looking For Arc Flash Safety Training? ACUTE Can Help!

With over 200 years of combined experience, ACUTE offers unparalleled safety expertise. Our instructor-led approach fosters a collaborative learning environment, ensuring your team gains practical knowledge and skills, including arc flash safety training.

We’ve served a diverse clientele across manufacturing, construction, healthcare, academia, and government, giving us a unique perspective on industry-specific safety challenges. Our proven track record, backed by countless positive reviews, is a testament to our commitment to excellence.

Contact us today to discover how ACUTE can elevate your workplace safety culture.