Many workplaces require some level of WHMIS symbols training. WHMIS stands for Workplace Hazardous Material Information System, and WHMIS training courses provide workers, employers, and supervisors with relevant information under WHMIS 1988 and 2015 ( the most up-to-date version) about the safe handling, storage, and usage of hazardous materials in the workplace. Training courses often include detailed quizzes used to test your knowledge and understanding of various aspects of the WHMIS training.

Here’s what you’ll learn in this guide:

- WHMIS Symbols

- Who Needs WHMIS Training (And When)?

- Employer Duties

- Worker Rights

- Why Is WHMIS Also Referred To As GHS?

For more information about WHMIS training or workplace health & safety training, contact the experts at ACUTE now!

1. WHMIS Symbols

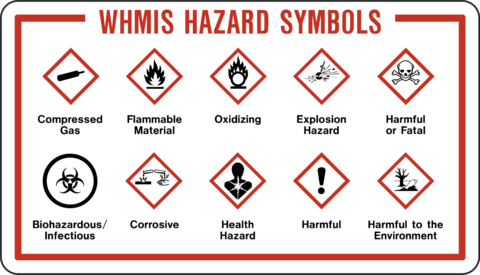

This image shows the WHMIS (Workplace Hazardous Materials Information System) hazard symbols, which are used in Canada to identify different types of hazardous materials. Each pictogram represents a specific type of risk associated with chemicals and substances in workplaces:

-

Compressed Gas – containers under pressure that may explode if heated.

-

Flammable Material – substances that can ignite easily.

-

Oxidizing – chemicals that can intensify a fire or cause explosions.

-

Explosion Hazard – materials that can explode due to heat, shock, or friction.

-

Harmful or Fatal – toxic substances that can cause death or serious harm if ingested, inhaled, or absorbed.

-

Biohazardous/Infectious – materials containing harmful organisms like viruses or bacteria.

-

Corrosive – substances that can burn skin, damage eyes, or corrode metals.

-

Health Hazard – long-term effects such as cancer, organ damage, or reproductive harm.

-

Harmful – materials that can cause less severe but still significant health issues.

-

Harmful to the Environment – chemicals that pose risks to wildlife or ecosystems.

These symbols are part of Canada’s WHMIS training system, helping ensure workers can quickly recognize hazards and handle materials safely. For expanded details on the WHMIS pictograms from the Government of Canada, click here.

2. Who Needs WHMIS Training (And When)?

Now that you know WHMIS symbols, it’s important to understand who needs training—and when.

If you are exposed to any chemicals or hazardous products in your workplace, you are required to complete WHMIS training. This applies to all workers—new and experienced alike—because WHMIS is designed to ensure everyone understands the hazards they may face on the job.

You may be surprised by what qualifies as a chemical hazard. Even common household products, like bleach, fall under WHMIS regulations.

WHMIS training is necessary in many sectors, including but not limited to:

-

Retail (handling cleaning agents, sanitizers, or aerosols)

-

Restaurants and food services (working with cleaning supplies and gases)

-

Healthcare and medical professions (exposure to disinfectants, medications, and biohazards)

-

Construction (using paints, adhesives, fuels, compressed gases, etc.)

-

Manufacturing and factory work (handling solvents, metals, and industrial chemicals)

And this list is not exhaustive. If your role involves working with—or even the possibility of exposure to—hazardous products, WHMIS training is mandatory.

When Will You Need WHMIS Training?

You will need WHMIS training if:

-

You may be exposed to chemicals or hazardous products during work activities (including normal use, maintenance, and emergencies)

-

You use, store, handle, or dispose of hazardous products and materials

-

You supervise workers who may be exposed to, use, store, handle, or dispose of hazardous products

-

You work in emergency response

By completing WHMIS training, you not only meet legal requirements but also gain the knowledge and confidence to keep yourself, your coworkers, and your workplace safe.

3. Employer Duties

Employer Duties Under the OHSA and WHMIS Regulation

The Occupational Health and Safety Act (OHSA) and the WHMIS Regulation clearly outline the responsibilities of employers in any workplace where hazardous products are used, handled, or stored. These laws are in place to protect workers and ensure safe working conditions. Employers cannot simply provide hazardous products and assume workers know how to manage them—there are strict legal obligations that must be followed.

Key Employer Responsibilities

-

Ensure that hazardous products are properly identified

-

Every hazardous product in the workplace must be clearly labelled with the appropriate WHMIS hazard symbols and information.

-

Employers must make sure labels remain legible, accurate, and up to date. This includes both supplier labels and workplace labels.

-

-

Obtain or prepare current Safety Data Sheets (SDSs) and make them available

-

An SDS provides detailed information about a hazardous product, including its properties, safe handling procedures, and first-aid measures.

-

Employers must ensure that an up-to-date SDS is available for every hazardous product in the workplace and that workers know where to access it.

-

SDSs must be readily available to workers, health and safety representatives, and members of a joint health and safety committee.

-

-

Provide instruction and training to workers who are exposed or likely to be exposed to hazardous products

-

Training must cover not only the identification of hazards but also safe use, storage, handling, and disposal practices.

-

Workers must also be trained on what to do in case of an emergency, including spills, leaks, or accidental exposure.

-

Training is not a one-time event—it should be refreshed whenever new products are introduced or workplace conditions change.

-

-

Assess biological and chemical agents produced in-house

-

If an employer manufactures or produces a biological or chemical agent for its own use, they are required to evaluate whether it meets the criteria of a hazardous product under WHMIS.

-

If the agent is hazardous, it must be labelled, documented with an SDS, and treated with the same level of control as any other hazardous product.

-

In short: Employers have a legal duty to protect workers by identifying hazards, maintaining accurate safety information, ensuring proper training, and evaluating any substances produced internally. These steps are essential not only for compliance but also for fostering a safe and healthy workplace.

4. Worker Rights

One of the three basic rights that the Occupational Health and Safety Act (OHSA) guarantees to all workers is the right to know about hazards they may be exposed to on the job. This right is central to WHMIS.

Through WHMIS, workers gain access to:

-

Labels on hazardous products that identify key risks and safe handling procedures.

-

Safety Data Sheets (SDSs) with detailed information on each hazardous product.

-

Training and instruction to ensure they understand how to use, store, and dispose of hazardous products safely.

In addition, workers have the right to be consulted through their joint health and safety committee (JHSC) or health and safety representative on how WHMIS training is developed and implemented. This ensures that training reflects real workplace conditions and worker concerns.

Worker Responsibilities Under WHMIS

While the OHSA and WHMIS give workers important rights, they also outline responsibilities to help ensure workplace safety. Workers must actively support the successful implementation of a WHMIS program by:

-

Reading and following instructions on product labels and Safety Data Sheets (SDSs).

-

Following workplace procedures, including the proper use of personal protective equipment (PPE).

-

Participating in WHMIS instruction and training, and applying what they learn on the job.

-

Asking questions if unsure about how to safely use, handle, or store a particular product.

-

Reporting hazards or contraventions to their employer or supervisor—for example, if a product arrives without a proper SDS, or if a label is missing or illegible.

In summary: Workers not only have the right to know about hazards but also play a critical role in maintaining a safe workplace by staying informed, following procedures, and reporting issues as they arise.

GHS stands for the Globally Harmonized System of Classification and Labelling of Chemicals is a worldwide standard for identifying and communicating chemical hazards. Developed by the United Nations, it provides a consistent framework for classifying hazardous products, creating safety data sheets (SDS), and designing labels.

The goal of GHS is simple: make chemical safety information universal. Instead of each country using its own rules—and sometimes multiple overlapping systems—GHS sets one clear standard that can be adopted worldwide.

For employers and workers, this means easier compliance, lower costs, and safer workplaces.

According to the Canadian Centre for Occupational Health and Safety (CCOHS), the GHS provides several key benefits:

-

Reduces compliance costs for businesses operating across borders

-

Promotes regulatory efficiency and consistency

-

Improves clarity of hazard communication for workers

-

Strengthens emergency response to chemical incidents

-

Reduces the need for duplicate testing, including animal testing

In short: it saves companies money and helps protect workers everywhere.

GHS and WHMIS in Canada

In Canada, GHS is implemented through the Workplace Hazardous Materials Information System (WHMIS). The latest Hazardous Products Regulations (HPR) came into force on December 15, 2022, aligning WHMIS with GHS Revision 7 and elements of Revision 8.

Suppliers and employers have until December 14, 2025, to transition completely. This means all labels, SDSs, and classifications must meet the new requirements by that deadline. Training for workers must also be updated to reflect the new standards.

What’s New in 2025? Global Updates

1. Global – GHS Revision 11

Adopted in December 2024, GHS Rev. 11 takes effect in September 2025. Key changes include:

-

A new climate hazard class for chemicals that contribute to global warming

-

Updated label elements, including new pictograms and hazard statements

-

Refinements to skin sensitization testing and classification

2. United States – Hazard Communication Standard (HCS) Update

On May 20, 2024, OSHA updated its HCS to align with GHS Rev. 7. It became fully enforceable on July 19, 2024, with updates such as:

-

Standardized 16-section SDS format

-

Labels with clearer hazard communication and QR code options

-

Faster SDS updates (within 90 days of new hazard info)

3. Canada – Transition Period Ends December 2025

-

Current rules align WHMIS with GHS Rev. 7/8

-

All suppliers and employers must update labels and SDSs by December 14, 2025

-

Guidance released in June 2025 clarifies differences with U.S. rules

4. Japan – Aligning with GHS Rev. 9

Japan is updating its JIS standards in 2025 to align with GHS Rev. 9, including refined rules for explosives classification.

5. European Union – Unique Formula Identifier (UFI)

By 2025, all hazardous products in the EU under the CLP Regulation must feature a UFI code on labels to help identify mixtures in emergency cases.

Trust ACUTE For WHMIS Symbols Knowledge and Training

ACUTE offers a half-day (4 hours) WHMIS 2015 (GHS) training course. ACUTE’s experienced instructors provide a great classroom learning experience with both face-to-face interactions and detailed handouts and quizzes. Training topics included in ACUTE’s WHMIS GHS training course include:

- Explanation of the employer, supervisor, and worker responsibilities

- How to recognize, assess, and control risks & evaluate the effectiveness of controls

- How to understand WHMIS labels

- How to understand WHMIS symbols and understand the hazards that each symbol represents

- Learn to understand the significance of signal words

- WHMIS Symbols Quiz

- WHMIS Test Answers and Hints

ACUTE helps organizations understand their training challenges while also taking care of the most crucial aspect of a safety program: providing unparalleled tailoring and customer service. Here are just a few things you can expect when training with ACUTE:

- Open Door Instructor-Student Partnership – ACUTE’s training services emphasize client participation. Staff want to build relationships with clients and serve as a touchstone for advice anytime moving forward.

- Serving Your Team and Industry – With a vast array of clients in manufacturing, construction, health, academic, and government agencies, ACUTE brings the best safety practices from across the spectrum to your workplace.

- 100 Years Combined Experience – ACUTE provides comprehensive health and safety training, on-site safety services, and consulting services. With over 100 years of combined experience, our staff offer more than theoretical or abstract ideas. ACUTE offers solutions.

- Track Record of Success – ACUTE is rated 4.9/5 stars on Google reviews, demonstrating a commitment to our clients, quality, and passion for training.

ACUTE is located in Waterloo, Ontario and services customers from cities such as Toronto, Mississauga, Brampton, Hamilton, Milton, Kitchener, London, Guelph, and other cities across Ontario.